Gịnị bụ Induction Hardening?

Kedu ihe bụ Induction Hardening?

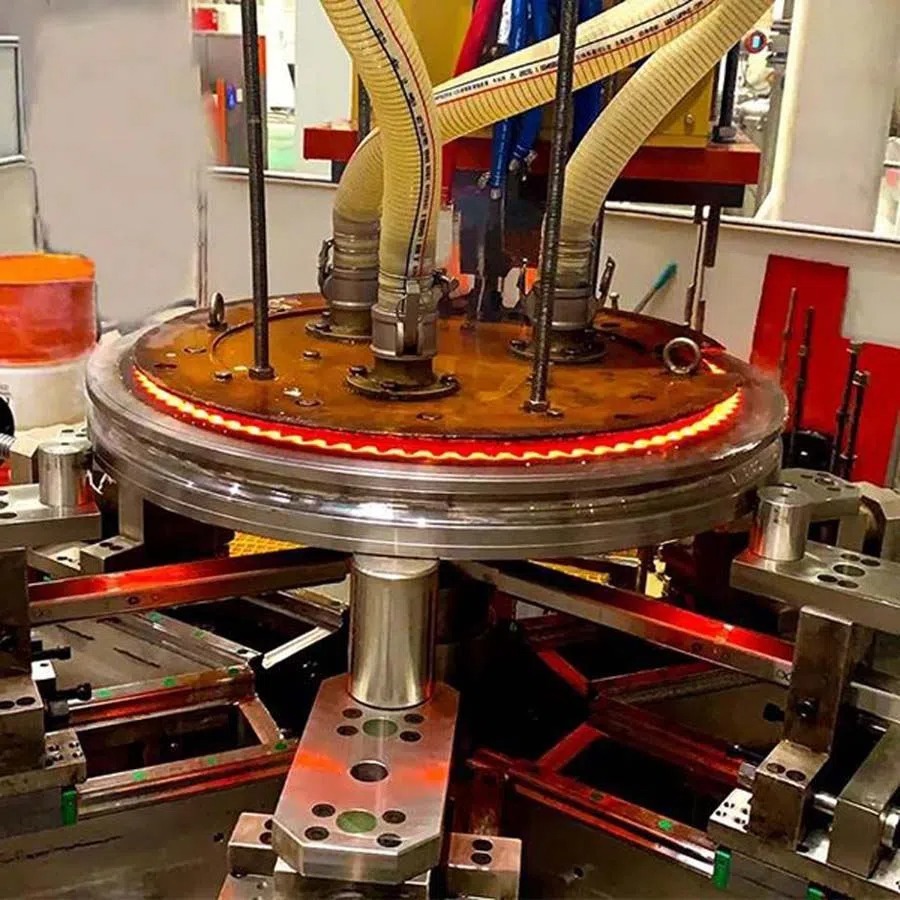

Induction hardening bụ usoro nkwụsị nke na-eji ụkpụrụ nke induction electromagnetic na-eme ka workpiece gbutu ahịrị oghere magnet n'akụkụ ebe ndọta ọzọ wee mepụta ugbu a n'elu akụkụ igwe. Dị ka mmetụta akpụkpọ ahụ nke mgbanwe mgbanwe, elu nke akụkụ ahụ na-ekpo ọkụ na-ekpo ọkụ ngwa ngwa n'ụdị eddy current na mgbe ahụ induction quenching ngwa ngwa.

mgbe igwe induction igwe eji eme oku emecha kpo oku na quenching usoro, metal akụkụ elu hardness dị elu, isi na-ekwusi ezi plasticity na siri ike, na-egosi ala notch uche, otú mmetụta siri ike, ike ọgwụgwụ, na eyi iguzogide na-mma nke ukwuu. N'ihi obere oge kpo oku, oxidation elu, na decarburization nke akụkụ dị ntakịrị, ma e jiri ya tụnyere ọgwụgwọ ndị ọzọ na-ekpo ọkụ, ọnụ ọgụgụ jụrụ nke akụkụ ahụ dị ntakịrị. Na-ahọrọ induction kpo oku ikuku kwesịrị ekwesị na-arụ ọrụ dị mkpa n'ọhịa nke ọgwụgwọ okpomọkụ induction metal.

Kedu ihe kpatara eji usoro ịgba ume induction?

Induction quenching bụ usoro nke na-eme ka mmiri dị n'ime igwe arụ ọrụ site na induction electromagnetic na arụ ọrụ ahụ na-ekpo ọkụ. Tụnyere teknụzụ kpo oku igwe nkịtị, teknụzụ induction quenching nwere uru ndị a:

1. The metal workpiece elu isi ike dị elu. Isi ike nke elu nke workpiece siri ike site na ikpo ọkụ dị elu na nke ọkara bụ 2 ~ 3 HRC dị elu karịa nke nkwụsị nkịtị. Mmetụta ígwè ya siri ike, ike ike ọgwụgwụ, na nguzogide eyi na-akawanye mma nke ukwuu. Enwere ike ịgbatị ndụ ọrụ nke ihe eji arụ ọrụ igwe site na induction quenching.

2. The metal workpiece abụghị integral kpo oku, otú na induction hardening, workpiece n'ozuzu deformation bụ obere;

3. The metal workpiece kpo oku oge dị mkpụmkpụ, elu ọxịdashọn decarburization ego bụ obere;

4. Na-ekpo ọkụ isi iyi na-arụ ọrụ na metal workpiece elu, kpo oku ọsọ na arụmọrụ dị elu;

5. Nhazi akụrụngwa mmenyụ ọkụ induction dị kọmpat karịa ngwa igwe induction igwe kpo oku nkịtị, dị mfe iji rụọ ọrụ.

6. Igwe na-agba ume induction na-achọpụta nhazi usoro ọgwụgwọ okpomọkụ na akpaghị aka, na-echekwa ọnụ ahịa ọrụ.

7. A nwekwara ike iji teknụzụ hardening induction dị n'elu ike na ikpo ọkụ ntinye yana ọgwụgwọ okpomọkụ kemịkal.

Kedu otu esi ahọrọ usoro mmetụ ike nke dabara adaba?

Usoro ike ike induction nwere ọtụtụ ụzọ kpo oku na ha niile nwere ihe arụ ọrụ kpo oku kwesịrị ekwesị.

1. Usoro ịgba ume ọkụ induction otu oge:

Okpomọkụ mmeghe nke otu oge ma ọ bụ kpo oku induction n'otu oge bụ usoro siri ike nnabata a na-ahụkarị. Mgbe usoro a na-eji tubes akụkụ anọ gbara gburugburu workpiece elu maka kpo oku rotary, a na-akpọkarị ya Single Shot.

Uru nke usoro kpo oku induction a bụ imezu ihe niile dị n'elu ebe ọrụ induction ọrụ kpo oku n'otu oge. Ya mere, ọrụ ya dị mfe, nrụpụta dị elu, ọ dị mma maka ikpo ọkụ na mpaghara workpiece adịghị oke ibu. N'ihi na kpo oku na karịsịa nnukwu ebe workpiece, ịmụta otu oge kpo oku usoro, ọ na-achọ bukwanu ike na elu ulo oru mbo na-eri.

Ihe atụ ndị a na-ahụkarị nke ịgba ume ọkụ induction otu oge bụ obere modul modul, ogwe mkpuchi mkpuchi CVJ, ụzọ ịgba ọsọ dị n'ime, wiil ndị na-ebu ụgbọ, wiil nkwado, ntụtụ mmiri, ndị na-adọkpụ, valvụ njedebe, valve rocker arcs, wdg.

2. Usoro nyocha nnabata nnabata:

Mgbe ebe ikpo ọkụ na-arụ ọrụ dị ukwuu, ọkụ ọkụ induction dị ntakịrị, a na-ejikarị usoro a eme ihe. N'ebe a, ebe a na-ekpo ọkụ gbakọọ S na-ezo aka na mpaghara nke mgbanaka induction dị. Ya mere, otu ike njupụta, na igwe induction igwe eji eme oku ike achọrọ bụ obere, asọmpi induction hardening machine Ọnụ ego ntinye ego dị ala, dabara maka obere mmepụta ihe ike induction induction, ihe atụ ndị a bụ nnukwu mkpanaka piston, mpịakọta corrugated, mpịakọta, pipeline mmanụ, mkpanaka sucker, ụgbọ okporo ígwè, ígwè ọrụ ụgbọ okporo ígwè na ihe ndị ọzọ.

3. Usoro mmenyụ kpo oku nkeji nkeji otu oge

Ihe atụ a na-ahụkarị bụ ọtụtụ camshafts induction hardening, oge ọ bụla na-ekpo ọkụ otu ma ọ bụ karịa cams, mgbe emechara oge a induction quenching, kpo oku akụkụ cam ọzọ, gia na-agbaze ezé site ezé nwekwara ike ịgụnye na nke a.

4. Usoro mmenyụ nyocha mmeghe nke nkeji nkeji

Ọmụmaatụ a na-ahụkarị bụ valvụ rocker shafts ma ọ bụ ihe ngbanwe ọsọ ọsọ induction hardening, ebe a na-enyocha ọtụtụ akụkụ nke osisi maka induction quenching, obosara quenching nwere ike ịdị iche, na ezé site na nyocha nha nha nha nwekwara ike ịgụnye na ngalaba a.

5. Induction kpo oku na imenyụ na mmiri mmiri

Induction hardening quenching na mmiri mmiri pụtara ụda ntinye na workpiece kpo oku elu na-mikpu na induction quenching mmiri mmiri, kpụ ọkụ n'ọnụ, n'ihi na kpo oku elu ike njupụta ịbụ ukwuu karịa gburugburu quench mmiri jụrụ ọnụego. Ya mere, elu na-ekpo ọkụ ngwa ngwa. Mgbe inductor na-agbanyụ, elu nke workpiece na-esi ike n'ihi na okpomọkụ absorption nke workpiece isi na jụrụ nke quenching mmiri mmiri.

Usoro a na-adabara n'ozuzu maka ígwè workpiece nke na-achọ obere ihe jụrụ oyi. Mgbe etinyere workpiece n'ikuku ma gbanyụọ eriri induction, ọkụ nke elu ahụ na-etinye obi n'etiti etiti ọrụ ahụ. Mgbe ọnụ ọgụgụ dị jụụ nke elu ahụ na-ekpo ọkụ dị ukwuu karịa ọnụ ọgụgụ dị egwu dị egwu, a na-eme ka ọrụ ahụ sie ike, nke yiri nkwụsị na mmiri mmiri.

Kedu ihe bụ akụkụ nke sistemu hardening induction?

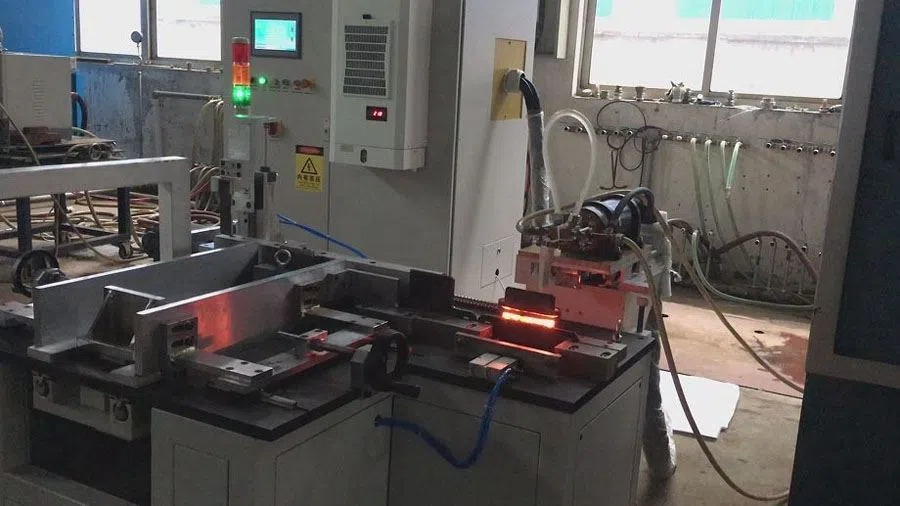

Ihe mejupụtara nke zuru oke igwe na-ekpochapu ume n'ozuzu na-agụnye ihe ọkụ ọkụ induction ọkụ ọkụ, CNC induction hardening machine tool, induction hardening coil, na inyeaka usoro mgbasa ozi mmiri jụrụ oyi na ịkwụsị usoro mgbasa ozi mmiri.

Modern induction kpo oku akụrụngwa emepụta, a bukwanu akụkụ nke ike ibido zuru ezu tent nke induction hardening akụrụngwa na turnkey oru ngo, onye ọrụ si ebelata mmepụta okirikiri, na-ezere n'ihi na otutu ọkọnọ ngalaba na usoro nke debugging bụ adabako, na ogologo debug ọrịa dị ka oge. Ntinye nke akụrụngwa zuru oke na ọrụ ntụgharị abụrụla ụzọ asọmpi maka ndị na-emepụta akụrụngwa.

Na mkpokọta, Dị ka otu n'ime ndị na-eduga induction hardening sistemu na-emepụta na China, anyị enyerela ọtụtụ puku ụlọ ọrụ na-ahụ maka ọgwụgwọ okpomọkụ aka ịchọta ngwọta ọgwụgwọ okpomọkụ induction kwesịrị ekwesị ugbua, yabụ iji jide n'aka na usoro mmechi nke induction siri ike dabara adaba. Biko ị nwere ike hapụ m ka m nweta eserese akụkụ ike gị, ihe, ike na arịrịọ miri emi, anyị nwere ike ịnye gị ntụnye aka nka nke usoro ikpo ọkụ ọkụ ọkụ metụtara ya yana mpempe akwụkwọ. Daalụ.

Sistemu na-eme ka ike na-agwụ ike n'ime igbe ikpe akụkụ ngwa

1. Na-atụ anya vetikal raceway CNC induction quenching igwe usoro

2. Chain Plate Induction hardening System

3. Cantilever gear CNC induction hardening machine system

4. Ikuku Ike Bolt Induction Quenching na Tempering System Production Line

5. Balanced aro shei n'ime oghere induction kpo oku hardening usoro

6. Nnukwu Mill Roller Induction Hardening